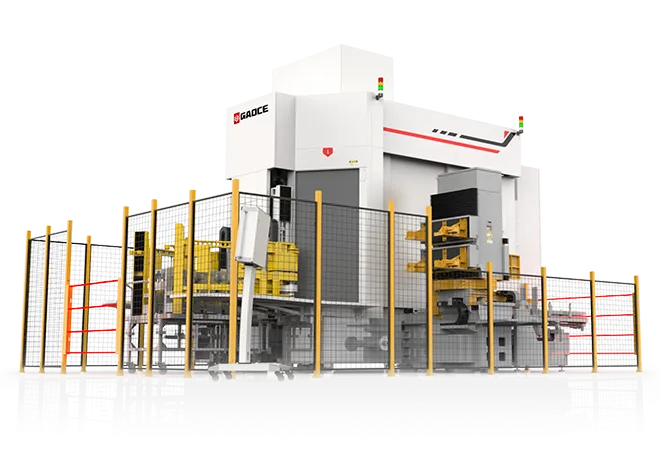

FC-1004Silicon Wafer Cutting Fluid

Silicon wafer cutting fluid refers to a key water-based additive used in the multi wire slicing process for silicon wafer manufacturing, which assists diamond wire saws in high-precision slicing of silicon ingots and bricks. It is sprayed into the slicing area through a circulation pipeline, lubricating and cooling the slicing area, and timely cleaning and dispersing the generated si-kerf particles, thereby improving the quality of silicon wafers and enhancing slicing efficiency. The FC-1004 silicon wafer cutting fluid developed and produced by Gaoce has good lubrication, cooling, cleaning, and dispersing effects, which can significantly improve the slicing yield, especially A grade wafer yield, reduce wire breakage rate, and improve TTV, saw marks and other indicators. At the same time, it is safe, environmentally friendly, easy for treatment, and complies with RoHS, REACH and other standards & regulations.

Product Parameters

Item |

Physical and Chemical Indicator |

||

Appearance (original solution) |

Colorless to pale yellow transparent liquid |

||

Cloud point (original solution) |

45 - 48 ℃ |

||

COD value (original solution) |

900,000 to 1.2 million ppm |

||

Density (original solution, 25 ℃) |

0.99 - 1.03 g/mL |

||

Volatile content (original solution) |

53.0 - 57.0 % |

||

PH value (1wt%, 25 ℃) |

6.0 - 6.4 |

||

Conductivity (1wt%, 25 ℃) |

≤40μS/cm |

||

Static surface tension (0.2wt%, 25 ℃) |

28 - 31 mN/m |

||

Related Products

Relevant Cases

Sustainable Development

Related Solutions

Get Quote

Fill in a brief message and we will contact you as soon as possible~