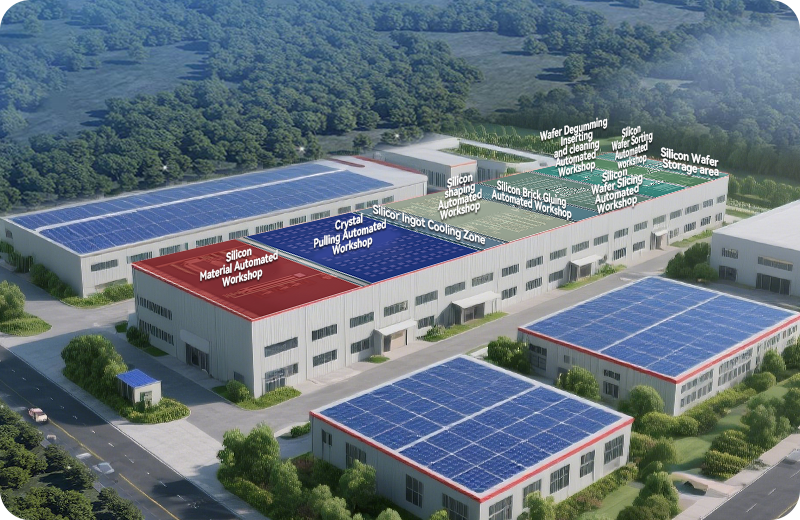

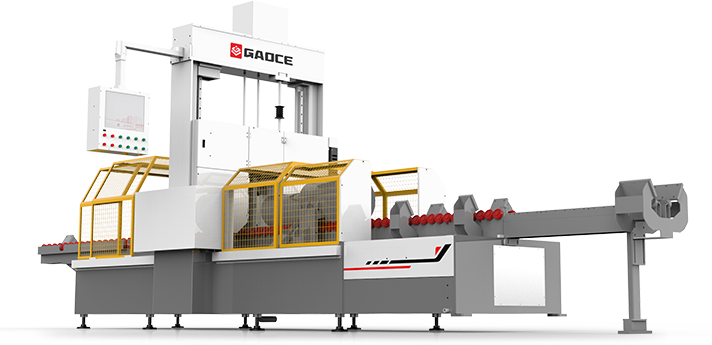

Leveraging profound technical expertise and operational experience, Gaoce provides industry clients with comprehensive wafer production factory-level solutions. This one-stop service encompasses factory planning and design, configuration of fully automated intelligent equipment for all processes, and integrated automated production lines. Currently, Gaoce wafer production factory-level solutions have won high recognition from customers worldwide, including Adani, India’s only vertically integrated company covering crystal pulling, wafer slicing, cell production and module production, Türkiye’s vertically integrated companies, such as KalyonPV, CW Enerji and Fellow Energy, as well as Corning and Hanwha Qcells from the high-end North American market. All core equipment for the customer’s Phase I project was supplied by Gaoce Meanwhile, Gaoce provides various value-added services, including technical support, centralized control, on-site service, and training, successfully eliminating the customer’s concerns regarding production and operations.